THSVC’s parent company: From its beginnings as “Tung Ho Hang” to today’s Tung Ho Steel

From its beginnings in “Tung Ho Hang” to today’s Tung Ho Steel Enterprise Corporation, the company has always made trustworthiness the company’s spiritual essence in its business. The company’s core business values and objectives are embodied in the pursuit of exceptional contributions to society.

Trustworthiness does not merely represent the company’s trustworthiness in relation to outside parties, customers, and society, but also signifies trustworthiness in its employees and in itself.

In Vietnam, THSVC also upholds the philosophy of trustworthiness and insists on positive pursuits and interactions as well as quality guarantees. This is our fundamental motivation and the starting point of our value and dignity. We dare to innovate the future. We stride forward with our heads held high as we carry out our ongoing operations.

Self-discipline. Love of knowledge. Optimism.

Self-discipline implies the exclusion of distracting thoughts, doing one’s utmost in practical work, and accepting challenges;

Love of knowledge implies striving in the pursuit of knowledge, delineating right and wrong, and pursuing excellence;

Optimism implies dealing tolerantly with others, proactively seeking progress, and achieving new innovations.

As epitomized by the corporate spirit in the corporate identity system of our parent company, Tung Ho Steel, we have the self-discipline to steadily and persistently gain a solid footing, while our passion for knowledge and our optimism allows us to progress and develop with vibrancy.

Insisting upon the philosophy of placing quality, integrity, and customers first

A persistent business approach that seeks stable and healthy success through innovative change

Focusing on the achievement of enterprise-oriented business, management informatization, and technology-centered production

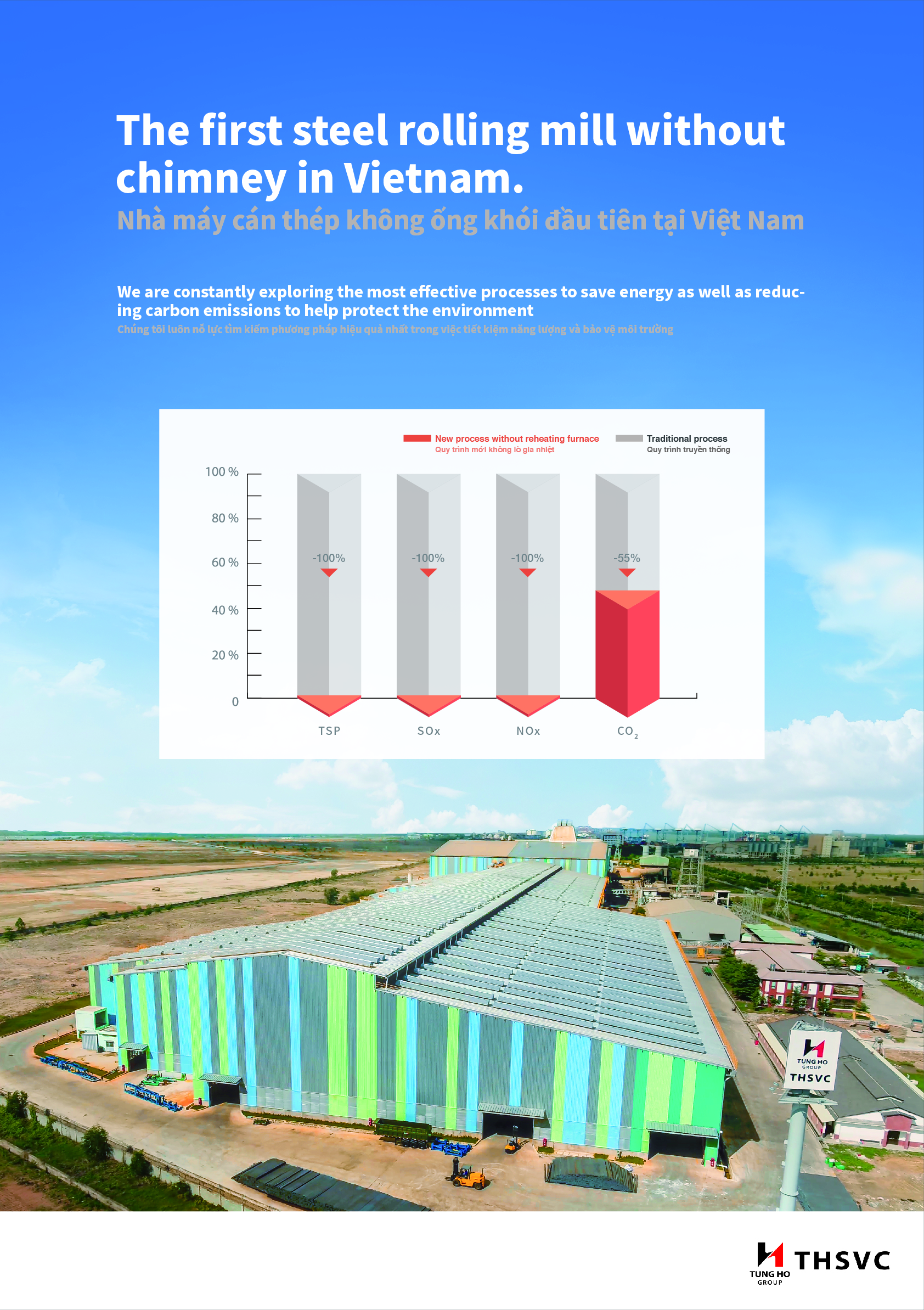

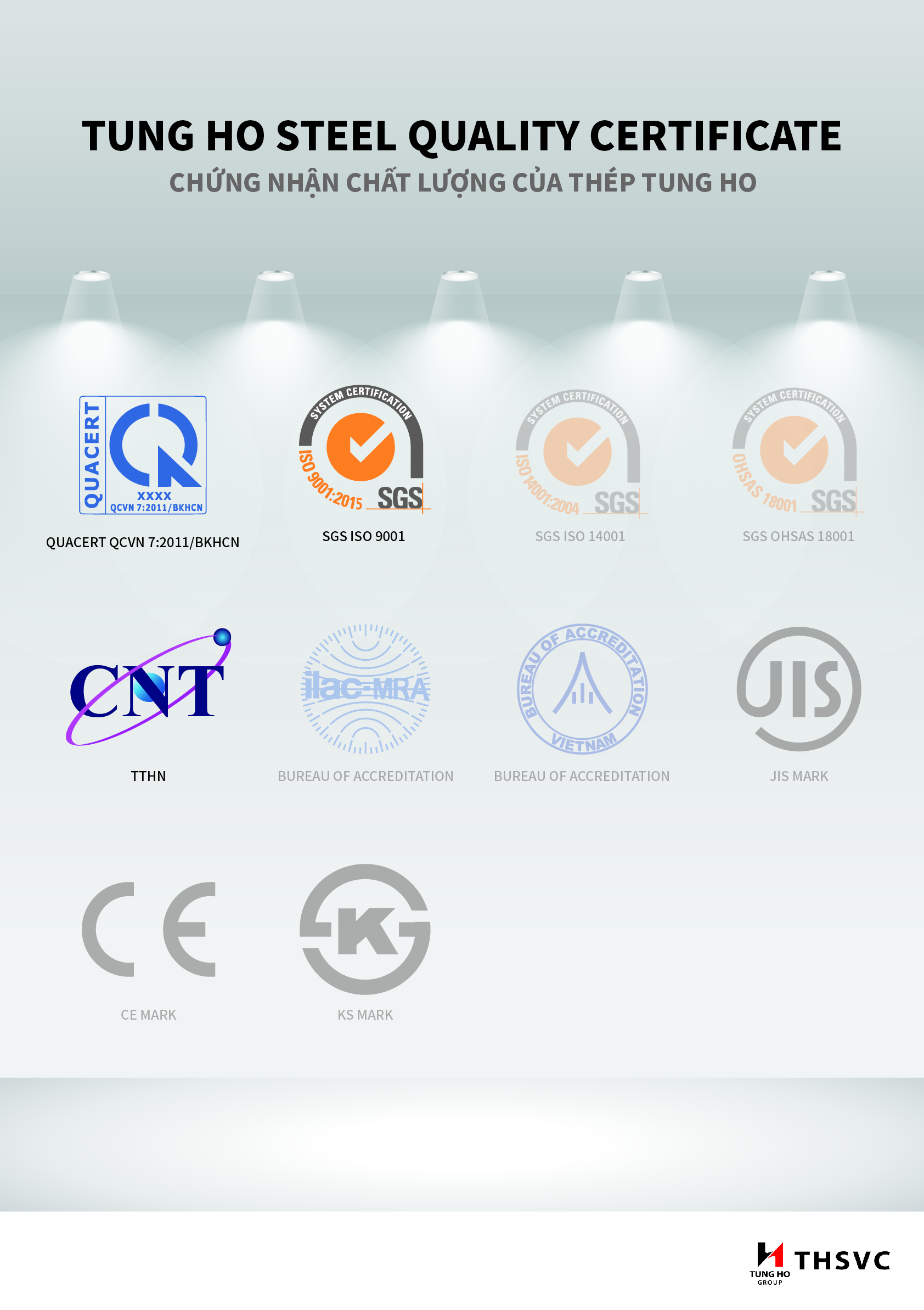

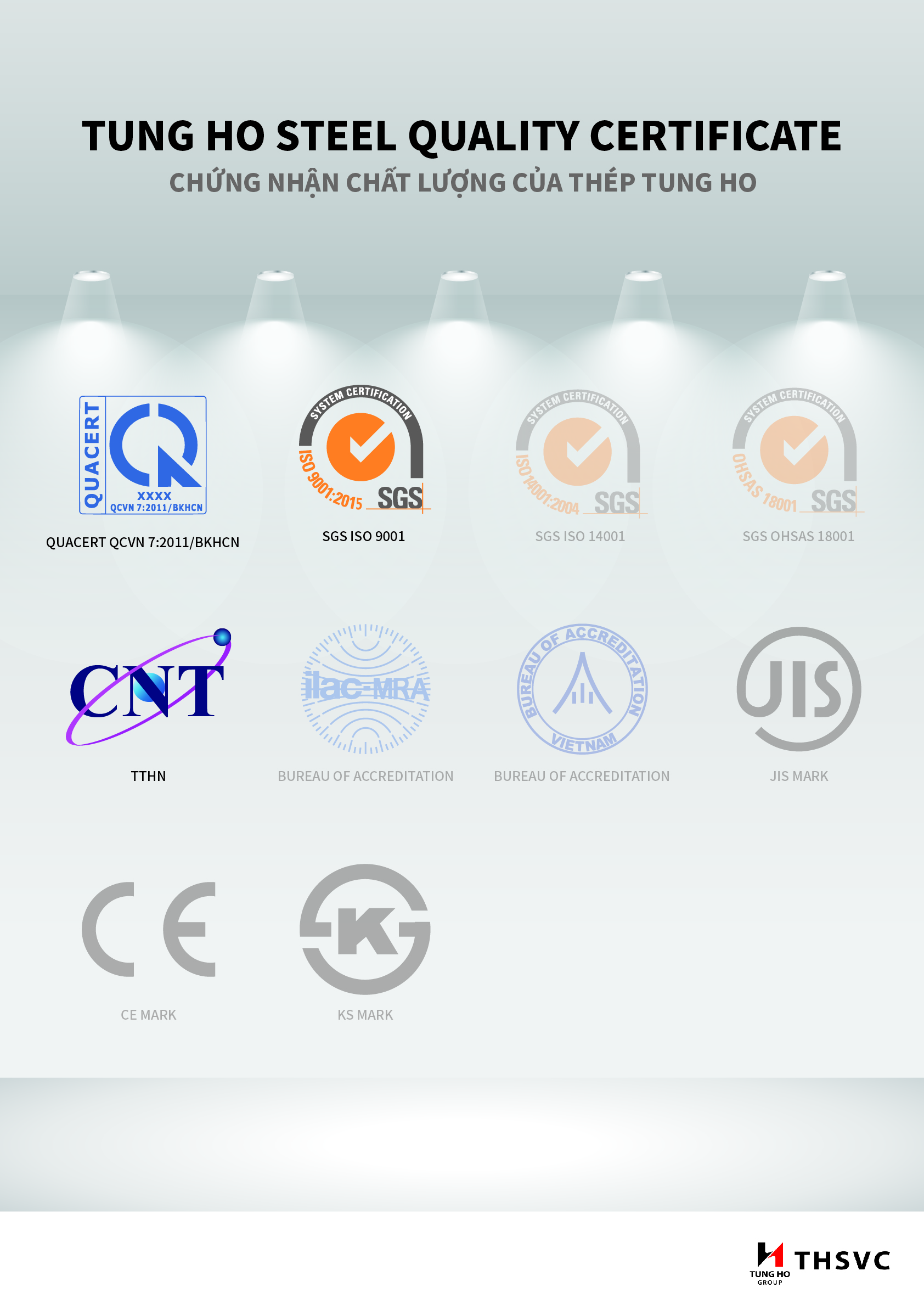

In line with the philosophy of our parent company, Tung Ho Steel, of ensuring product value, Tung Ho Steel strives to provide safe services involving quality steel building materials. As always, our products have received positive recognition by the market and customers, with quality and value far above industry standards. Our market share is among the highest in Taiwan every single year. In the past, in addition to plants receiving honors for high-quality products, we have also received a variety of international certifications such as ISO, UL, DQS, and BS. We have even passed the Japanese Ministry of International Trade and Industry JIS (Japan Industrial Standards) MARK plant certification. In terms of laboratories, each plant has been certified by the Taiwan Accreditation Foundation (TAF), which directly attests to our guarantee of high quality for all products. At the same time, for products offered by Tung Ho Steel, strict product verifications have been obtained from the Department of Rapid Transit Systems, the Ministry of National Defense, nuclear power stations, the American Bureau of Shipping, Det Norske Veritas, and Germanischer Lloyd. All of these attest to our product quality, integrity, and our insistence that customers always come first.

In April 2016, after acquiring Fuco Steel (renamed THSVC), Tung Ho Steel actively brought in the ISO 9001: 2015 edition of quality management system counseling. It also engaged Vietnam’s renowned new management consulting and training company, INNMA, to provide education and training on the concept of quality management systems in Chinese and Vietnamese as well as to provide professional coaching. The goal is to enable all THSVC employees and plants to comprehensively meet operating standards and to raise employees’ quality management skills. We hope that with all employees participating in quality management system activities, we will continually improve the performance of every department so that we can provide products and services that satisfy the needs of domestic and overseas customers.

Testing and calibration laboratories operate in accordance with ISO / IEC 17025.

In addition to providing highly reliable test results based on a rigorous quality management system and standardization of test methods.

From practical experience as well as proficiency testing assessments, interlaboratory comparisons.

Currently, ISO/IEC 17025 accreditation certificate is considered to be the highest value of customer trust and the reliability.

In order to promote the testing ability and level of the laboratory and personnel.

So that the test results can meet the credibility of the market.

An external counselling company Quatest3 arrange experts to the THSVC conduct training.

Finally, in January 2020, the company was accredited by the national certification body BOA of Vietnam to get physics and chemistry laboratory of THSVC obtained mechanical and chemical field ISO / IEC 17025 certificate.

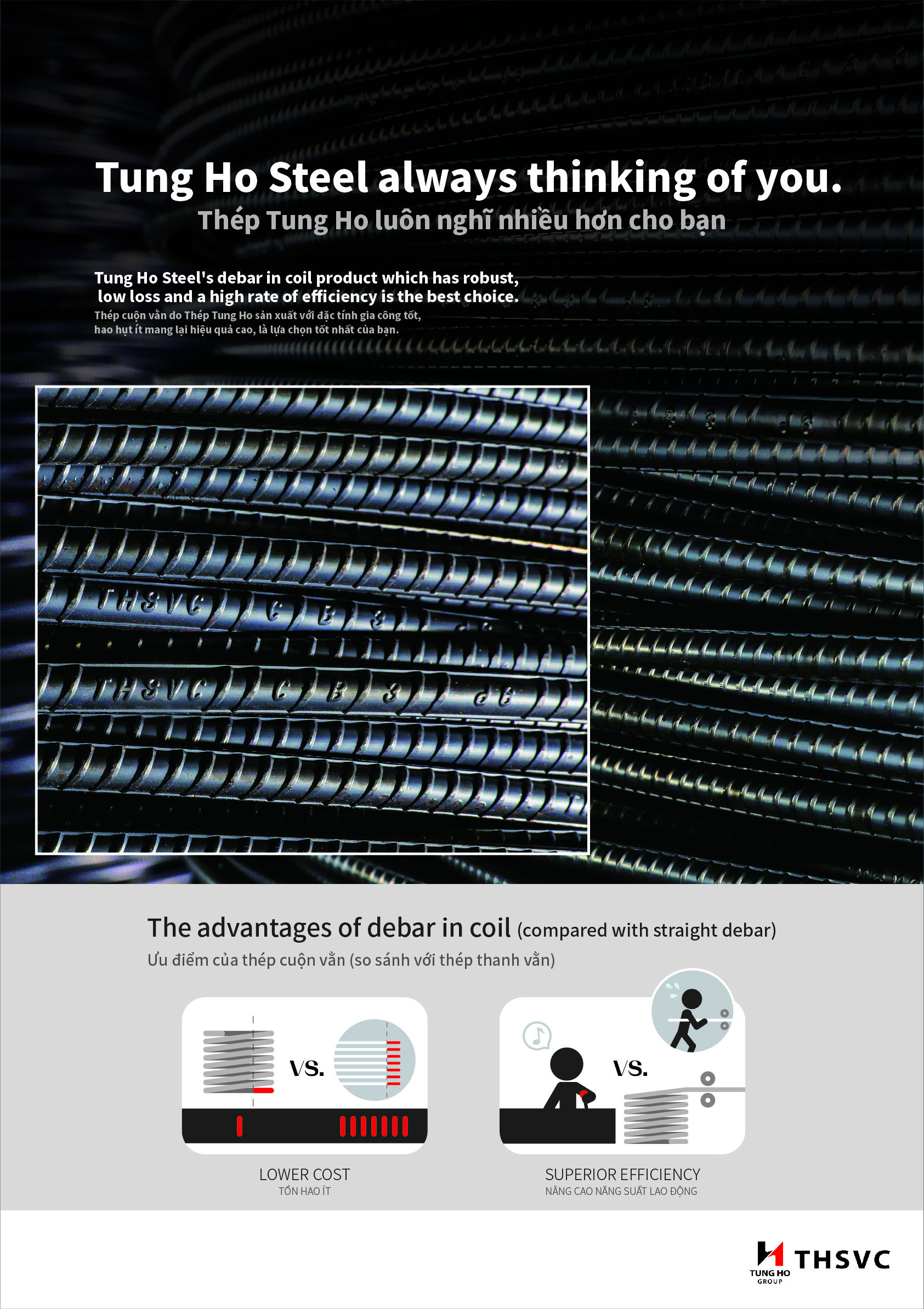

Tung Ho Steel Meets Quality Standards Of Reinforced Concrete.

The set of standards of TCVN 1651, Reinforced concrete, includes the following standards:

- TCVN 1651-1: Steel for the reinforcement of concrete - Plain bars.

- TCVN 1651-2: Steel for the reinforcement of concrete - Ribbed bars .

In order to fulfill the market's demand for product quality.

THSVC obtained Quatest3 and Quacert national product specification TCVN 1651-1: 2018 wire rod size 6mm ~ 16mm all steel grades and TCVN 1651-2: 2018 full sizes and all steel grades approval certificate.

Our declared product quality philosophy:

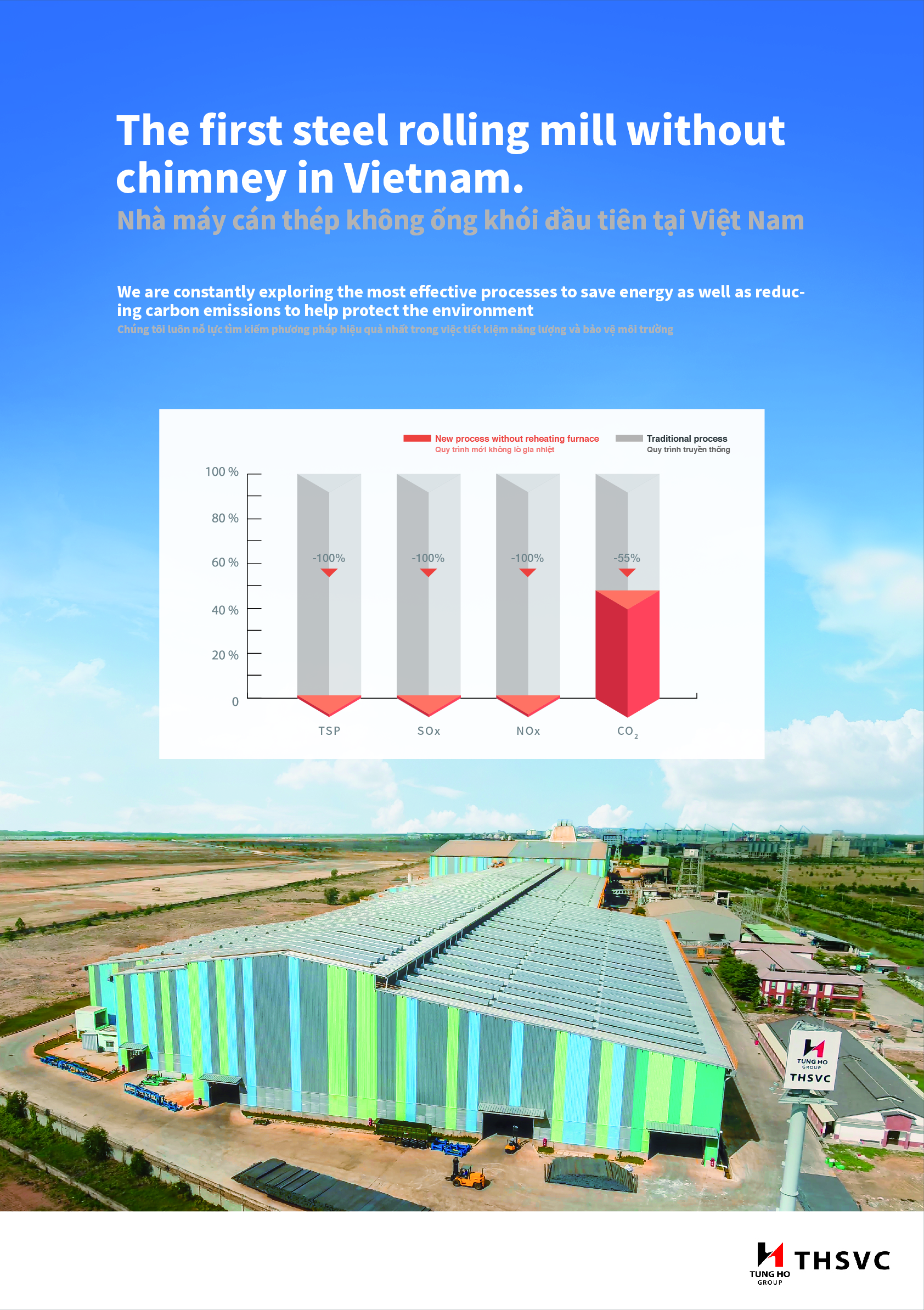

To seek ongoing innovations to improve product quality, satisfy customer needs, and promote a cleaner environment

- What we promise:

- To strive to establish, implement, and maintain a comprehensive product quality management system and to continuously improve product quality management system effectiveness.

- To continue to learn about and satisfy customer needs as part of our philosophy of placing customers first.

- To produce products that comply with relevant legal norms and customer requirements.

- To meet the product delivery timeframe expected by the customer during the work cycle.

- To rely on company-wide communication to learn about and ensure all employees participate in product quality management system operation, so as to achieve ongoing improvements in the performance of various departments.

- To formulate work standards and implement employee training, so that all employees are provided with the knowledge to promote usage of the product quality management system and to achieve product quality objectives.

- Through management review mechanisms, product quality policy applicability is reviewed, and annual product quality goals are set for each work unit to achieve continuous improvements to the product quality management system.